Structure

ENGINEERING

ENGINEERING

The design-build process is a journey from concept to completion. It involves the understanding of spaces on a multitude of levels, and one aspect of that is the engineering of the physical structure. A sustainable engineering process is an extension of the design. It requires a scientific understanding of structural requirements and material properties, and efficient engineering and construction using that understanding. Craft is an integral component of the design-build collaboration .

At Malhar, this has been possible only with the enthusiastic participation of craftspersons and engineers who share the passion inherent in the design. This collaborative process also allows a flexibility to innovate during the entire process. Adaptable and versatile project management and execution are made possible because of our hands-on team, a building culture we actively promote.

CONSTRUCTION

The challenges of implementing innovative techniques and non-standard details at the scale of Malhar have been significant. Our approach to addressing this has been to create small groups comprising architects, engineers and craftspersons that work together on ground, plugging into the big picture.

Improving the quality of work and making the efforts of labour more efficient has been a cornerstone of our approach. Skills and craft have been given their due and promoted on par with professional expertise. Certain materials and processes have been mechanised, and better tools and equipment have been used to shift the focus to quality of work. Efforts have been made to change the attitude from cosmetically treating poor work to consciously building with pride. The attention to detail is seen in every aspect of the structure: foundations, walls, roofs, basements, staircases, openings and woodwork.

FOUNDATIONS

Load bearing vs Framed structure:

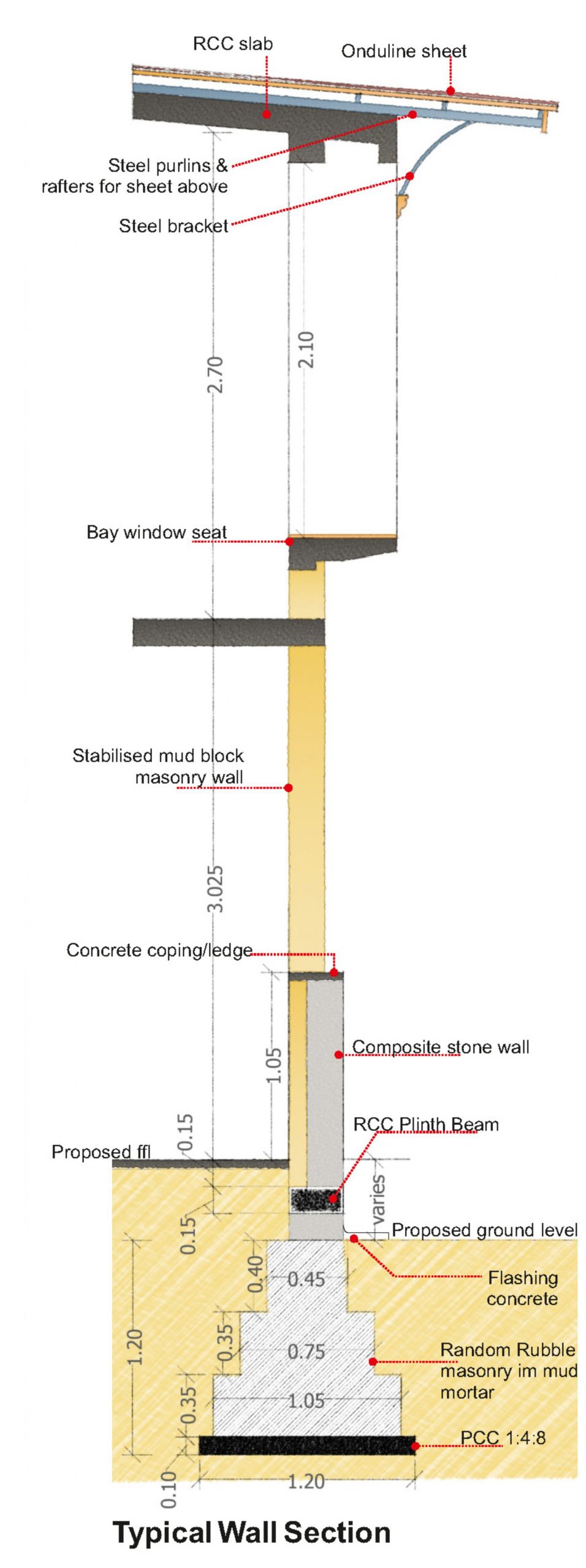

Homes in Malhar are primarily load-bearing, augmented with the use of reinforced concrete where necessary. The foundation is load bearing, built using locally available granite stone. A plinth beam acts as a tie above this and is a precautionary measure for seismic stability.

For the spans of spaces involved, a load bearing structure is more than sufficient. A framed structure would require the same thickness of masonry, which are adequate to support the load. A load bearing building also reduces the use of cement and steel, which are high in their energy consumption.

WALLS

The walls across Malhar are built with a variety of materials. Local stone and compressed stabilized mud blocks are seen in the cluster and townhouses. For the apartments, hollow terracotta bricks in combination with mud blocks were used to create a cavity wall. Rammed earth has been used for compound walls.

THE COMPOSITE STONE WALL

The composite stone wall was developed as a structural element. It is a combination of external fabric of stacked local stone, with compressed stabilized mud block masonry on the internal edge.

This serves many purposes. The stone creates a visually high plinth, above which the exposed mud blocks can be built. The blocks are protected from rain water backsplash by the stone. The internal mud block wall is convenient to take services through, as it can be cut easily.

The combination creates a more horizontal proportion, and enhances the low-scale experience on the campus.

The typical wall section represents the houses that have been built as ground and one upper storey.

RCC footings and plinth beams have been used in areas where the soil bearing capacity is not sufficient for a load-bearing structure. The footings extend up to the plinth beam level, the structure then becoming load bearing above ground. Individual RCC columns are used in large spanned spaces.

ARCHES & LINTELS

Openings in the structure present another avenue for design. We have used a combination of stone and concrete lintels across the campus. In later phases, we introduced mud block arches as features once the skill to build such arches had been developed.

Lintel sizes have been matched to the brick courses, and reinforcement designed accordingly, both for aesthetics and for ease of construction. Smaller openings have been fitted with local chapdi stone left exposed as a feature in the design. These openings include niches along staircase walls and in other areas.

STAIRCASE

In our earlier projects, we developed expertise with the folded plate concrete stair. At the scale in Malhar, it was difficult to control the quality and maintain accuracy of risers and treads. The required attention to detail tended to slow down the process of construction. Staircase finishes were another challenge, both for the material and in fixing of the railing. Wood was ultimately the preferred finish.

Taking all considerations into account and after discussions with the carpentry team, we decided on the use of timber staircases. They were not only easy to build, but would also add lightness to the space.

The railing detail was worked out with posts at the landings and the railing a truss that spanned the posts. This could be prefabricated and installed- making the process a lot cleaner and the finish neater. For shorter flights masonry was used to give more stability to the post. The landings were worked out with a concrete beam to house the wooden beam.

These stairs came with their own set of challenges, but this remains our preferred choice for the staircase.

ROOF

The standard sloping roof is cast in reinforced cement concrete with an efficient structural design. As mentioned, the ventilated cavity is created in two ways – using a corrugated sheet or hollow terracotta blocks. The sheet overhang has been used innovatively with steel brackets, creating a newer aesthetic. This evolved as a result of being an appropriate solution for waterproofing and heat insulation.

For semi open spaces like verandahs and car parks, the structure is a combination of a steel beams and wooden rafters. This ensures a balance of cost, aesthetics and space. We have used Mangalore (terracotta) roofing tiles wherever the slope is sufficient. These are comfortable to sit under and have a pleasing ambience. They do require some maintenance, as they damage easily and sometimes shift and need to be adjusted. When the form required has been flat, we have used polycarbonate sheets or glass. These have inherent issues of heat being trapped under and being difficult to clean. They need to be designed well and used appropriately.

WOODWORK

Woodwork at GoodEarth has been one of the jewels in our crown. With a talented pool of carpenters, we have sustained our choice of building doors and windows in wood. The details of wooden balcony railings, verandah pillars, jaalis and other decorative features bring out the character of the spaces. Very often these details form the face of our work.

It is a source of pride to have been able to use the craft contextually and to involve the carpenters in the process. The timber used at Malhar is a combination of honne, recycled teak and pinewood. Economically sized sections and effective joinery, along with strict processes of seasoning, have made this material work for us.

BASEMENT

We experimented with vaults in some of our basement structures. In collaboration with scientists at IISC, we developed vaults both as retaining walls (built using concrete blocks) and as a roof structure (built using soil cement blocks). It was a slow process requiring multiple skills and constant coordination to complete the task. We did not take it forward to future phases, due to the complexity of the process and the scale of the project.